① polymer reactionary sand: high molecular weight reactionary sand uses selected calcium sand as the main material, adds operational additives and is subjected to high -temperature calcification for the formation of a protective layer on the surface of the sand. Quantity ...

① polymer reactionary sand: high molecular weight reactionary sand uses selected calcium sand as the main material, adds operational additives and is subjected to high -temperature calcification for the formation of a protective layer on the surface of the sand. The number of cells is 30-80, and the appearance is mainly milk-white. It is mainly used for the surface of not asphalt high molecular weight self -adhesive roll waterproof materials. It has the properties of protection against punctures, high and low temperature, etc., which allows you to achieve high -quality waterproofing.

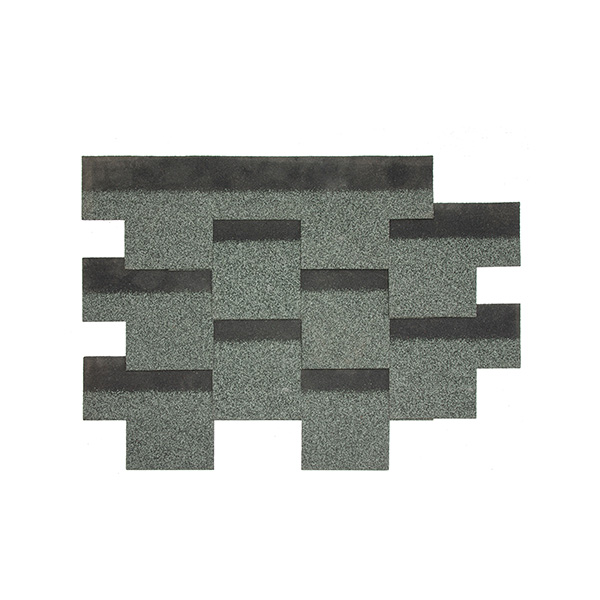

② Shannet: a high -quality basalt was chosen as the main material. After high -temperature pumping, it has strong hydrophobic and stable characteristics. The sorting is from 20 to 40 shirts. It is mainly used for waterproofing rolls with SBS sandy surface to prevent prolonged air on the rubber layer and waterproofing rolls and the effect of natural conditions such as temperature and light on them, which leads to a deterioration in the characteristics of the material. He also plays a certain aesthetic role.