China: What kind of water -soluble coatings are better for the plant?

The choice of water -soluble coatings for industrial facilities, such as factories, is an important step that affects the durability of equipment, employees' safety and the economic efficiency of the enterprise. The variety of water -soluble colors and varnishes can confuse, but the right choice depends on the understanding of the specifics of the production and needs of a particular object.

Factors determining the optimal choice

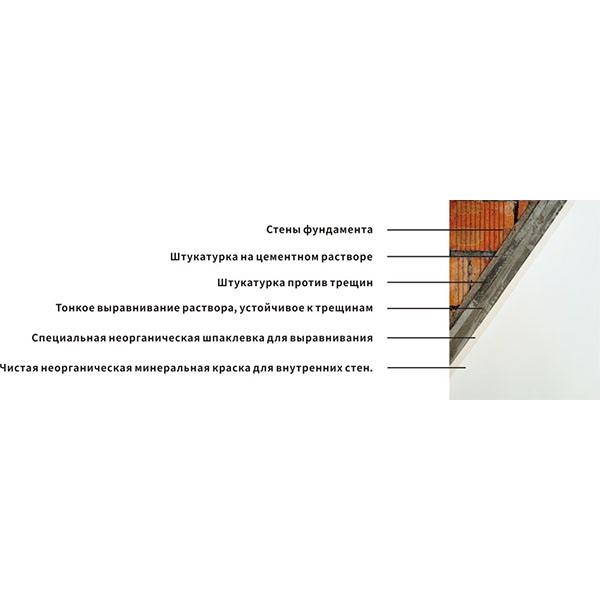

Before choosing a coating, it is necessary to take into account several key points. First of all, these are features of production itself: the presence of aggressive chemicals, humidity, temperature, mechanical loads and purification frequency - all this affects the requirements for resistance and wear resistance of the coating. For example, in a workshop with intense mechanical influences, a coating with high abrasive resistance is required. The type of equipment on which the coating will be applied is also important: machines, pipes, tanks - each has its own characteristics. Finally, the project budget plays a decisive role, since prices for water -soluble coatings can vary depending on their composition and characteristics.

Comparison of the types of water -soluble coatings

Various types of water -soluble coatings have different properties. Acrylic enamels, for example, are well suited for coatings that require high wear resistance and resistance to chemical influences of medium intensity. Polyurethane enamels offer higher resistance to aggressive environments and high temperatures, which makes them an excellent choice for workshops with special conditions. Some varnishes may be the best option for decorative decoration, while maintaining good moisture resistance. It is important to remember that the characteristics of each type of coatings can vary depending on the manufacturer.

Choice recommendations

The best approach will be to contact specialists in the selection of coatings. They will be able to analyze specific conditions at the plant, given all the nuances of production, and offer the best option. They can also advise on the application and care of coatings, which will significantly affect their service life. In addition to professional assistance, it is important to study reviews about various types of water -soluble coatings. Based on the information received, you can make a reasonable choice that will meet your needs and budget. As a result, the competent choice of water -soluble coverage will not only improve the appearance of the enterprise, but also protect its equipment, which will ultimately affect its economic well -being.